The sign up the borders of Cropwell Bishop in Nottinghamshire welcomes people to a village 'famous for Stilton cheese’. The locals be proud of their cheese – my taxi driver states he puts Stilton in the lentil curry – because, just like champagne could be created only within the Champagne region of France, so Stilton can be created only in Leicestershire, Nottinghamshire and Derbyshire. Only six dairies are licensed to really make it at Cropwell Bishop they create almost 15 percent of Stilton.

'I prefer to say we’re the 3rd greatest and also the third tiniest,’ states Robin Skailes, 35, among the company directors from the family company, established by his grandfather Frank in 1941, who passed it onto his sons David and Ian (who are while retiring). The organization once made cheddar too, however focuses solely on Stilton now makes greater than 150,000 cheeses annually – blue Stiltons (organic and non-organic animal rennet and vegetarian), blue Shropshires and white-colored Stiltons. Production dramatically ramps up between August and December, ready for Christmas. In high season the creamery makes 500 Stiltons each day using 45,000 litres of milk. Staff figures swell from 60 mainly local employees to 85.

Your day starts at 4am, once the milk arrives from 14 Peak District farms and it is pasteurised and piped into two silver vats. Here starter cultures, Penicillium roqueforti (nowhere mould) and rennet (the enzyme that turns milk solid) are added. After 24 hrs the curd is drained and cut by hands to produce the whey protein. 'In bigger dairies this method is mechanised,’ Skailes states. 'But by doing the work by hands you receive a smoother taste.’

At 1.30pm every single day the curds are hands-ladled right into a draining vat. Four men outfitted in white-colored overcoats and wellies perform a nearly balletic dance, scooping the dripping curds in one vat, spinning around and sloshing them in to the draining vat behind. 'We treat the curds with many different respect,’ Skailes states. 'Hand-ladling protects it.’ Chris Dawson, a cheese specialist at Waitrose, that has labored using the creamery for ten years, concurs. 'The mixture of the special animal rennet they will use and also the hands-ladling provides it with a superbly balanced flavour with a lot of complexity it’s really moreish.’

Related Articles

Skailes thinks the dairy’s traditional techniques would be the answer to its many awards. Most lately it won a few only at that year’s Great Yorkshire Show, however the one Skailes is most happy with may be the engraved cheese board (they'd to come back the trophy) he was given after winning three golds for that Classic Blue Stilton and Organic Blue Stilton in the Nantwich Worldwide Cheese Awards last This summer. 'Winning gold there's like winning the Champions League,’ he states, smiling.

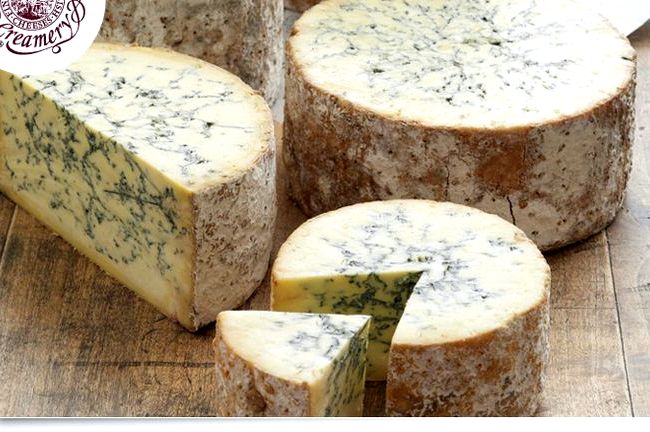

Cropwell Bishop Stilton during its various stages of maturation: hands ladling to split up the curds in the whey protein (left), the drained curds (center) pressed cheeses ready for that maturing rooms (STEVEN JOYCE)

The curds, the consistency of scrambled eggs, are spooned into 'hoops’ – small round moulds. 2 days later the hoops are switched over, to empty further. 'It’s bloody difficult,’ Skailes states. 'I drop them.’ 5 days later six women 'rub up’ the cheese – a conventional technique which involves smoothing lower the top of cheese using the flat of the knife. 'Some of those girls have been here in excess of 3 decades. They remember me growing up arriving plus they still let me know off,’ he states.

The applied cheese remains for any day prior to it being used in the very first of countless maturing rooms, in which the fruity aroma of three,000 cheeses instantly hits you. The smell within the second room, having a labyrinth of shelves that contains three- to four-week-old cheese, is more powerful. Right now the jackets around the outdoors from the cheeses have switched various shades of golden brown and mildew has began to look. 'We allow the coat grow naturally,’ Skailes states because he prods a cheese. 'This is loaded with lots of give also it’s sticky, that is a good sign.’ The label around the cheese truckles states '20th September’ – the date the milk was at the vat. 'Someone will eat this on Xmas Day,’ he states proudly.

After 35 days each cheese is defined right into a metal cylinder, individually, with 16 lengthy needles that pierce your skin and activate nowhere mould. After seven to ten days mould starts growing internally. When they're considered ready they're gone to live in the grading room. The development manager Howard Lucas, 54 ('the Stilton godfather,’ Skailes states), is peeking from behind a trolley that contains half a lot of cheese. No cheese leaves the dairy without his permission. He inserts a 'cheese iron’ to extract an example from the center of the Stilton to check it – he a treadmill of his team is going to do this to each single cheese. 'I didn’t like Stilton after i began 19 years back,’ he states. 'But now I'm able to’t go each day without eating it. I continued holiday this summer time and that i missed it a lot I needed to buy some.’ Every lunchtime Lucas eats a cake having a slice of Stilton on the top.

Skailes’s two- and 4-year-old sons help at cheese shows ('the grannies love them’), but he admits he didn’t help as he was youthful. 'I didn’t even enjoy the flavour of Stilton until I had been a grown-up.’ He labored for that local travel agent Trailfinders until six years back as he made the decision to stop his job and then leave London together with his wife and go back to Nottinghamshire to understand the household trade. Now he and the cousin Ben (who began working at the organization 2 yrs before Robin) are progressively overtaking using their fathers.

'It is an extremely traditional company,’ Dawson states. 'But Robin has an interest in pushing the barriers of cheesemaking, for instance getting back traditional techniques for example hands-ladling, which his grandfather might have used but that have been abandoned within the 1980s when mechanisation required over. It's why they produce things i think is the greatest Stilton. It’s very exciting dealing with them.’

Within the last 2 yrs Skailes continues to be creating a batch per week of the soft blue cheese, constantly tweaking the recipe for any cheese he hopes is going to be his 'legacy’. 'I’m still researching cheesemaking,’ Skailes states. 'But I believe my dad is simply too it’s a never-ending job. You’re never finished.’

Cropwell Bishop cheeses include Cropwell Bishop Blue Shropshire, 3.39 for 200g, and Cropwell Bishop Blue Stilton created using traditional rennet, 1.70 for 100g. They are offered at Waitrose (0800-188884 waitrose.com )